XVDEVIOS官方中文版APP下载

XVDEVIOS官方中文版APP下载Natural Dream Hill Brown Mattress

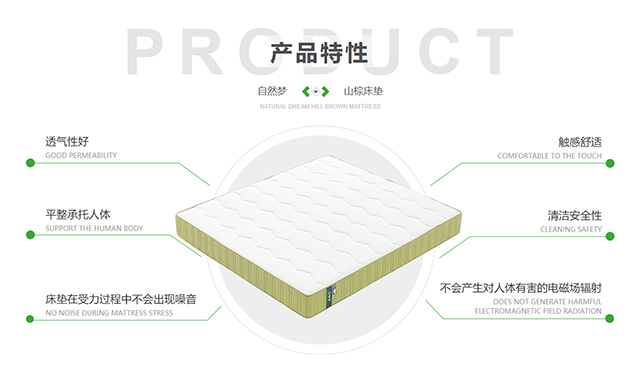

Good permeability

Support the human body

No noise during mattress stress

Comfortable to the touch

Cleaning safety

Does not generate harmful electromagnetic field radiation

宣传视频

宣传视频 XVDEVIOS官方中文版APP下载

XVDEVIOS官方中文版APP下载Natural Dream Hill Brown Mattress

河北XVDEVIOS安装包床垫有限公司创建于2017年4月份。创建之初就成功收购了“X站安卓下载安装”商标品牌。“X站安卓下载安装”成为XVDEVIOS安装包公司旗下品牌之一。XVDEVIOS安装包公司为把 “X站安卓下载安装”品牌发扬光大,进行了团队建设、设备更新、产品调整、家具配套等多方面的资源整合。并与红星美凯龙合作,所销售的产品实施识别防伪措施,以防假冒。

XVDEVIOS安装包•X站安卓下载安装XVDEVIOS官方中文版APP下载严格执行高要求的环保标准。打造强腰、护脊、易入睡的高品质产品。并推行免费试用60天的推广活动;销售网络已覆盖全国21个省市。X站安卓下载安装的目标是让消费者满意、让合作伙伴满意、让员工满意、让社会满意。

XVDEVIOS官方中文版APP下载

XVDEVIOS官方中文版APP下载Natural Dream Hill Brown Mattress

joining support

选择X站安卓下载安装的六大理由

franchise support

选择X站安卓下载安装的六大支持

way of joining

X站安卓下载安装合伙人全国招募

franchise process

免费索取样块和加盟手册 XVDEVIOS官方中文版APP下载

XVDEVIOS官方中文版APP下载Natural Dream Hill Brown Mattress